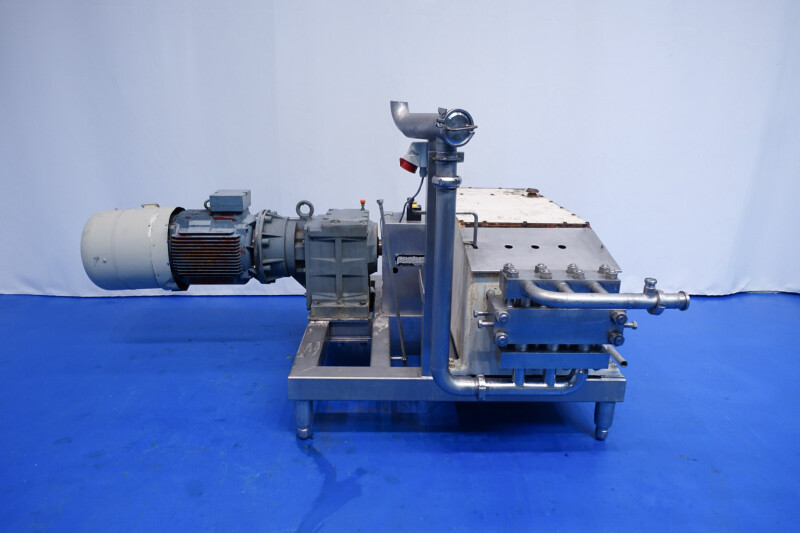

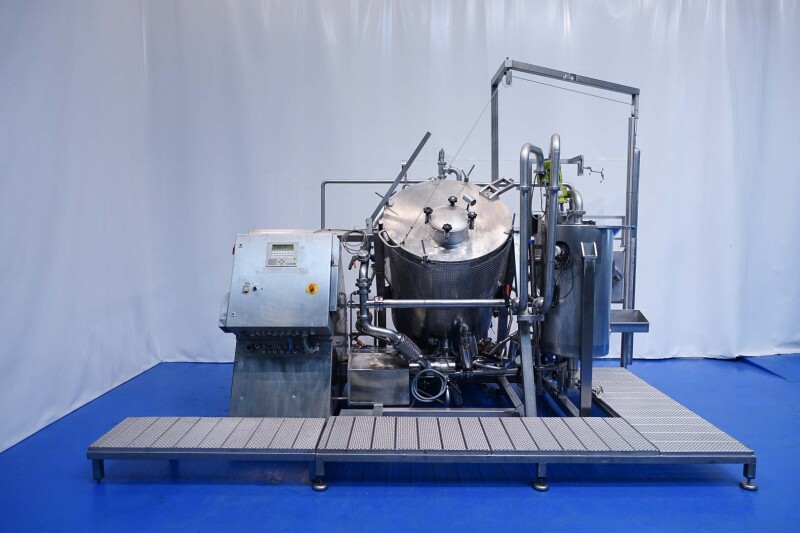

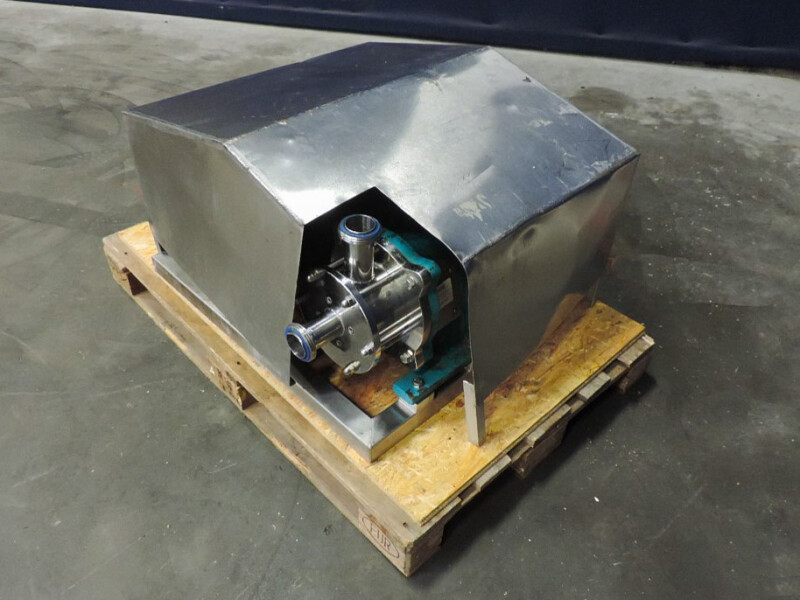

High pressure homogeniser

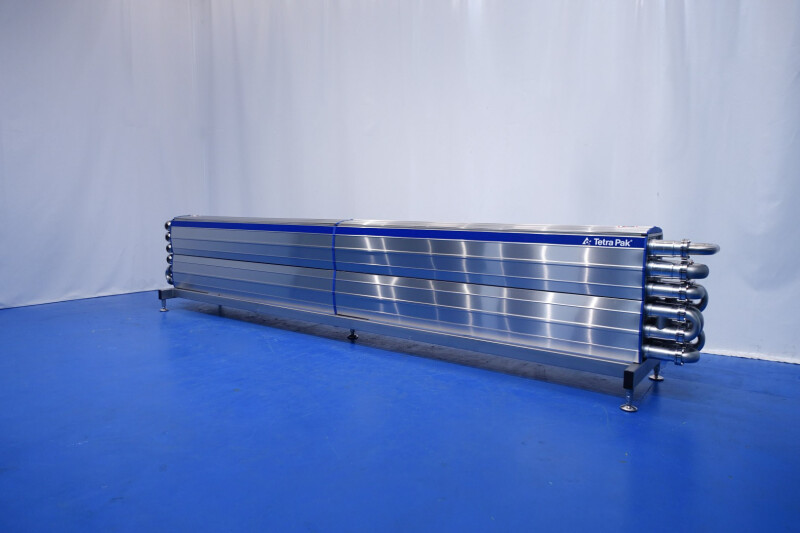

Manufacturer: Tetra Pak , Type: Tetra Alex 30

High pressure homogeniser. 2 stage with hydraulic pressure control. 3 Pistons, piston diameter: 63 mm and stroke: 135 mm. Stainless steel cladded and plating covered from the inside with sound proof material. Connections: 2x 2,5" SMS. Current motor power: 110 kW and max...

View machine